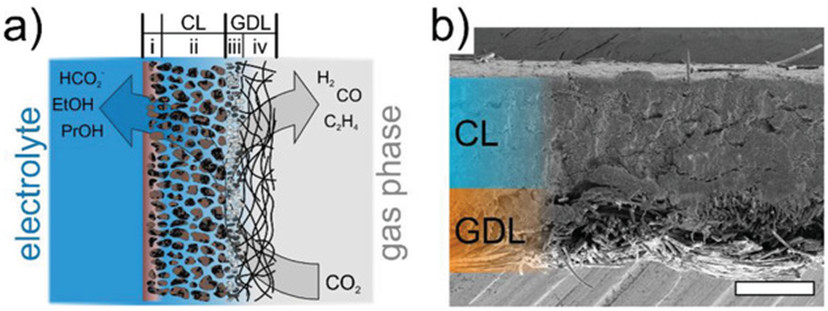

An active electrocatalyst can only reach its optimum potential when incorporated in tailored electrodes and reactors. Our group investigates a multitude of different reaction types, ranging from the electrochemical water splitting for both the hydrogen and oxygen generation, to the reduction of CO2 and CO to chemical synthons as well as electroorganic reactions. Evidently, each reaction type presents different demands and challenges regarding the criteria that an electrode must fulfill, such as electrical conductivity, tailored porosity, and mechanical stability. In addition, the catalytic layer deposited on an electrode must also be precisely tailored for the target reaction. Here, the hydrophobicity, ionic conductivity and thickness of the catalytic layer play a key role. Likewise, the reaction environment needs to be adjusted by careful optimization of the electrolyzers.

Our expertise lies on the generation of a holistic pathway from the design, testing and optimization of electrodes to establishing novel electrolyzers. This allows to ensure with confidence that once an active electrocatalyst for the investigated reaction has been identified, we are able to provide a clear and hurdle-free path towards a large-scale optimized electrode.